Overview

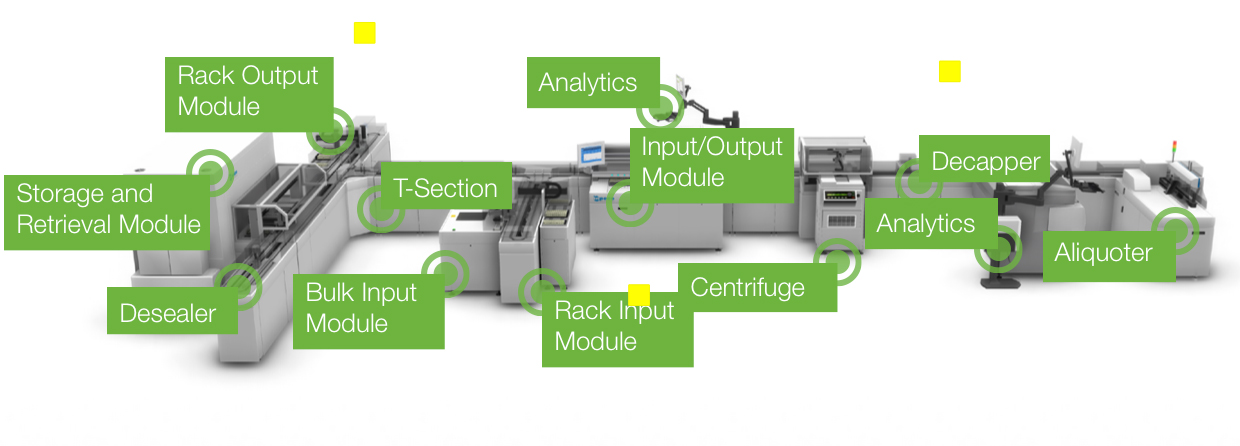

r The ACCELERATOR a3600 is a total laboratory automation system, designed to meet the challenges of clinical laboratories, both today and in the future. The ACCELERATOR a3600 combines con guration exibility, scalability and advanced analytical performance, ensuing the unique needs of your laboratory are met. Automation maximizes lab performance by easily and ef ciently managing uctuations in your daily workload. Whether your challenges are simple or complex, the ACCELERATOR a3600 provides a customized automation solution that optimizes performance and quality, ensuring your laboratory services operate at maximum efficiency.

Configurability

The ACCELERATOR a3600 provides your laboratory with the performance necessary to ensure high quality patient care, using unsurpassed con gurability and speed.

- Predictable and consistent result turnaround times are achieved even during the busiest periods.

- All ACCELERATOR a3600 systems handle multiple tube sizes and types simultaneously so there is no need to standardized tubes.

- Sample pathway traceability is accomplished using Radio Frequency Identi cation (RFID) tagged sample carriers, which are matched to the sample barcodes.

- The throughput of each module is optimized for performance and there can be be several of each module type on a track to meet individual laboratory needs.

Input/Output Module (IOM)

|  |

Rack Input Module (RIM)

|  |